We design, develop and manufacture the ideas of high technology industry with the best team and resources to achieve it.

Industries we participed

Electronic

Automotive

Pharmaceutical

Food industry

Footwear

Textile

Furniture

Capabilities

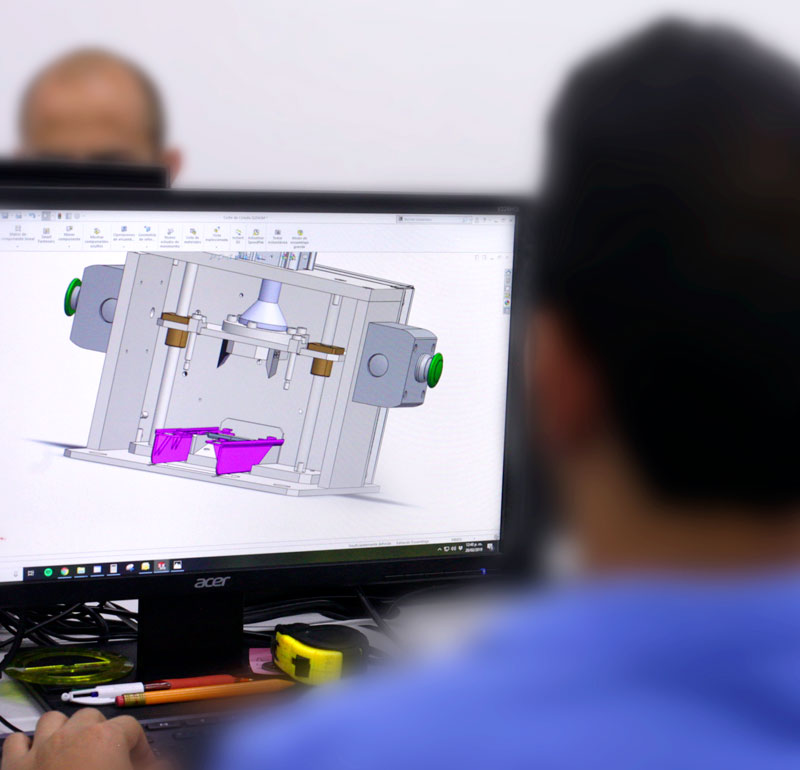

Design and development

Our D+D division , is composed of a multidisciplinary team of engineers, qualified in cutting edge technology to generate innovative and specialized solutions to the needs of all types of industries.

Our team is ready to make your projects come true from any idea.

- Automations.

- Specialized solutions.

- Manufacturing tools.

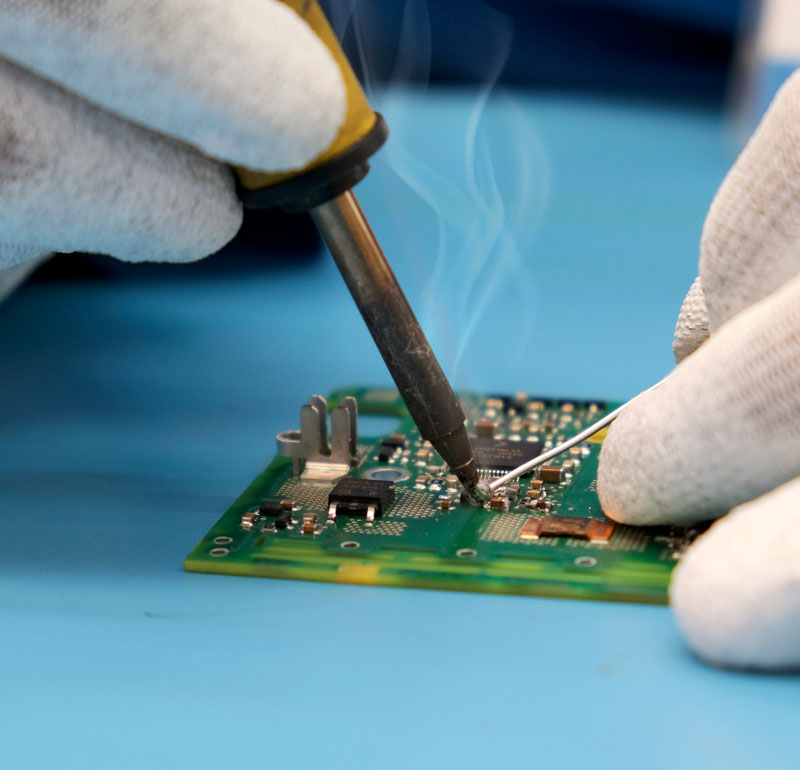

Manufacturing

We have the capacity to offer completely customized manufacturing solutions to the needs of our customers, we build a suit tailored to your projects.

Our company has the flexibility to adapt to already established processes and / or develop new processes.

We have standardized processes in 5's, ESD and certifications in IPC.

- Third level assemblies (box build)

- Manual welding components, cables and / or harnesses. (PTH)

- Electrical tests.

- Inspection / packaging.

- Application of conformal.

- Metal-mechanical assemblies.

- Our high mix, low volume approach.

Sorting

We have the qualified personal to realized any sorting, inspection and separation of any type of raw material and finished goods.

- Plastic materials. (Connectors, carcasses, etc.)

- Metallic materials. (Terminals, chassis, etc.)

- PCB. (Weld inspection, tracks, finishes, etc.)

- Materials of SMT and PTH. (Resistance, capacitors, etc.)

- Finished goods. (Complete assemblies, chassis, etc.)

Rework

Also, We have qualified personal to repair raw material and finished goods.

Repairs like:

- PCB: repair of tracks, pads, cosmetic damage, etc.

- Raw material: rework in metallic pieces, plastic, conectors, etc.

- Finished goods: chassis (scratches, bumps, paint damage, etc.) and assemblies (rearmed, repackaging, engineering changes, etc.).

Contamos con certificaciones ipc - 610, 600 y 7711/7721

Supply chain

In NGSSOL we know that a great part of the success of project comes to supply chain, to have the supplies (mro) of the best quality and that are delivered on time, to determine to a large extent the fluidity with which the rest of the processes are developed of a project. Our division of SC is fully aware of this and therefore, in order to provide our customers with quality supplies, at the best times.

- Safety and hygiene equipment. (boots, glasses, helmets, vests, etc.)

- Esd products and equipment (gown, heel cups, trays, insoles, mats, etc.)

- Chemical products.

- Adhesives.

- Packaging.

- Spare parts.

Fashion engineering

We optimize the production processes of the companies in the fashion industry, 40 years of experience support our commitment.

Applying new technologies, we improve production processes, managing to reduce development times by up to 5 times. arrollo.

- Design and development of ideas that provide clear solutions in online productions.

- Design of tooling, fixtures, jigs and gauges to optimize the process in the production lines.

- We train ourselves to keep innovating and stay one step ahead of market trends.